Although the nozzles are among the cheapest components of a sprayer, they are of great value in their ability to influence the performance of the sprayer. The nozzles measure the amount of liquid sprayed per unit area, controlling the application rate as well as the variability of the spraying on the width of the boom. The nozzles also influence the size of the droplets, affecting both the target cover and the risk of spray drift.

The primary objective of the nozzle is to transform the liquid vein into droplets and form the spray jet.

Agricultural spray nozzles come in many forms, but they can be grouped under the following main categories:

- Turbulence nozzles that produce a conical, solid or hollow jet

- Flat fan nozzle. Twin fan nozzle are also available

- Discs and Cores that produce a conical, full or hollow jet. Combinations of different Discs and different Cores provide a wide flow range

- Metering discs which serve to calibrate a flow rate. They are used alone in the case of pneumatic sprayers or in combination with other components on airblast sprayers.

Consequently, the choice of the nozzle as a function of the work to be carried out may seem complex. Indeed, the effectiveness of the application will be greatly impacted depending on whether or not the right nozzle is chosen.

The characteristics of a nozzle.

The characteristics of a nozzle can be numerous. However, the first ones to be considered are:

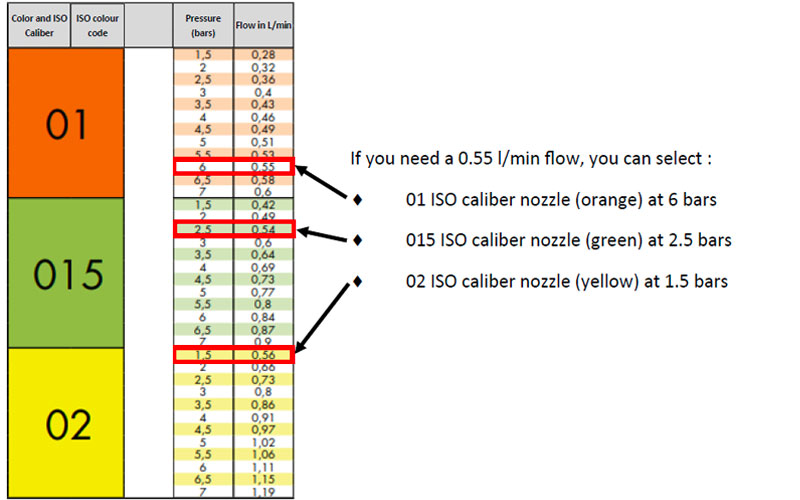

- The size : this is the flow rate, in litres per minute at a standardised pressure. This size is associated with a standardized colour. This is governed by ISO 10625. For example, a yellow ISO nozzle corresponds to a 02 caliber. In an imperial measure, this caliber 02 means that the nozzle has a standardized flow rate of 0.2 American gallon per minute at a standardized pressure of 45 PSI. In the metric system, this corresponds to 0.8 liters per minute at a pressure of 3 bars.

- The angle: although there is a great diversity of angles available, the vast majority of commonly used nozzles have an angle of 80 degrees or 110 degrees.

- The material : the nozzles may be offered in different materials. The most common are ceramic, plastic, stainless steel and brass. Ceramic nozzles are unanimously recognized as being the most resistant over time, and more particularly in applications requiring high working pressures. They are also particularly suitable when using hard waters, loaded with micro-abrasive elements orwhen the spray mixture is made from diluted powder.

- The spray pattern : although the most used are flat fan and hollow cone, there are also twin fan, off centered, ...

- The operating mode : in order to meet the requirements of spraying quality and protection of the environment, operatin mode has evolved evolved over time: so-called “standard”, “drift limited” or “air injection”. The aim is to provide more efficient nozzles in terms of drift reduction while maintaining the best spray quality.

- The recommended working pressure range: for each Albuz nozzle, we tell you a working pressure range in which you will get the best performance.

- Droplet size : crop protection work is multiple and influenced by the mode of action of the plant protection product used (contact, systemic), target (insects, fungal infections, weeds, fertilizers, etc.) and the growth stage of the crop (pre-raised, post-breeding, growth stage, culture density, etc.). Depending on these requirements, it is appropriate to select a nozzle which will produce the appropriate droplet size. For each of the Albuz nozzles, a table gives the class of droplet size according to the pressure. It is then possible to select, in the range of models and sizes available, the most suitable nozzle.

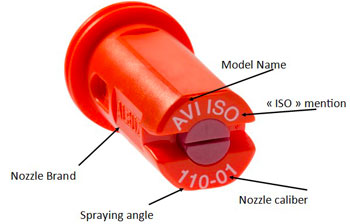

- The angle and caliber information is present on each nozzle. However, and in order to facilitate identification, some other information are also available:

N.B. : The Albuz range consists consists in so-called “ISO” nozzles and so-called “EUROPE” nozzles.

The “EUROPE” nozzles meet an Albuz classification for sizes (flow) and colour.

Practical example for choosing a nozzle

The choice is guided by different parameters :

- The volume to be applied per unit area. Most often expressed in litres per hectare

- The desired working speed, expressed in km/h

- The spacing between the nozzles, expressed in meters. The most common being 50 cm (or 0.5 m)

Depending on these parameters, there are various means to identify the most suitable nozzle :

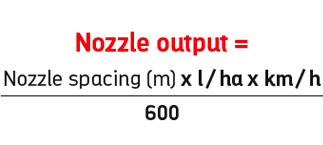

- There is a simple formula for determining the flow rate value in liter/minute of the nozzle which corresponds to the above criteria :

Once the flow rate has been calculated, you just have to refer to an ISO flow chart to identify a nozzle delivering this flow rate.

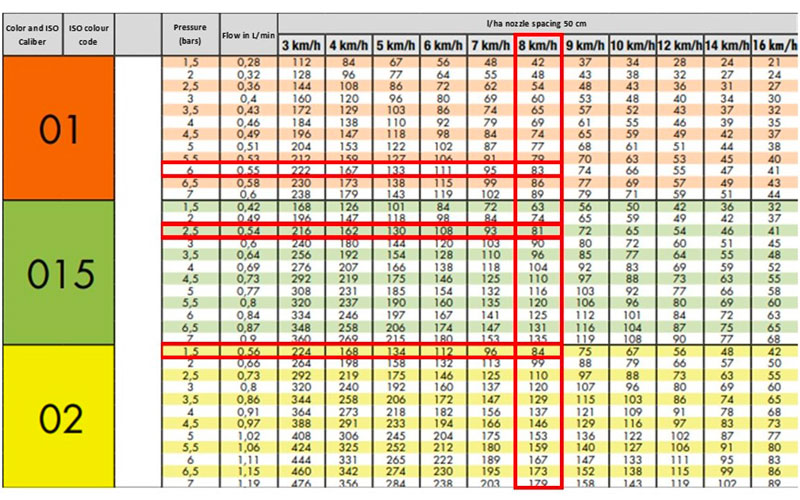

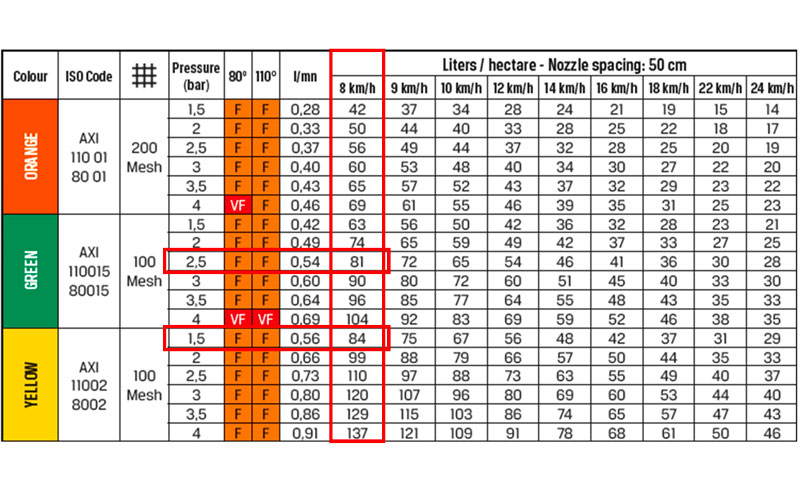

- You can refer to a pre-established chart (for 50 cm spaced nozzles) that allows you to search directly according to the parameters of rate per hectare and of working speed.

For example, if you need to spray 82 l/ ha at 8 km/h, you can quickly identify the possible nozzles.

Once the possible sizes have been identified, refer to the Albuz flow chart (which specifies the possible pressure range for each model as well as the droplet size spectrum).

Extract from the Albuz AXI nozzle flow chart

It can be seen here that only the sizes 015 (green) and 02 (yellow) are meeting the required criteria.

In addition, you can also find information on the droplet size spectrum (VF - Very fine / F - Fine / M - Medium / G - Coarse / VC - Very Coarse).

- Finally, you can use the mobile phone app Albuz (Android and IOS).

Very easy to use, this application allows you to quickly enter your settings to get the list of Albuz nozzle models that match.